Vacuum Interrupter for Circuit Breakers

|

|

Background |

Design |

|

CG commenced manufacturing of vacuum contactors in the year 2001-02. This technology has been developed in-house by CG. The vacuum contactors manufactured are in the kV range of 1.1 kV to 12 kV. Since then nearly 7000 contactors have been supplied to Indian and international customers. Salient features of CG make vacuum contactors:

|

The construction of the product is evaluated and validated by state-of-art electro static & magnetic field analysis software at our own R&D. This ensures uniform distribution of electrical and mechanical stress.

Applications

6. Transformer switching |

Typical Technical Data

Parameter |

Vacuum Contactor Type |

Units |

|

VC-400 |

VC-630 |

MVC-400 |

MVC-400L |

CS-VP11 |

CS-VP11L |

|

Frequency |

50/60 |

50/60 |

50/60 |

50/60 |

50/60 |

50/60 |

Hz |

Rated Voltage |

1 |

1 |

7.2 |

7.2 |

12 |

12 |

kVrms |

Rated operational current |

400 |

630 |

400 |

400 |

|

400 |

Arms |

Reference Standard |

IEC-947 |

IEC-947 |

IEC-470 |

IEC-470 |

IEC-470 |

IEC-470 |

___ |

Utilization category |

AC3/AC4 |

AC3/AC4 |

AC4 |

AC4 |

AC4 |

AC4 |

___ |

Rated Breaking Current |

3.2 |

5 |

3.2 |

3.2 |

3.2 |

3.2 |

KA |

Rated Making Current |

4 |

6.3 |

4 |

4 |

4 |

4 |

KA rms |

Short Time Current/Time |

3.2 |

5 |

3.2 |

3.2 |

3.2 |

3.2 |

KA rms |

Dielectric withstand(P.F for 1 min) |

10 |

10 |

20 |

20 |

28 |

28 |

kVrms |

BIL withstand(1.2/50 micro sec) |

36 |

36 |

60 |

60 |

75 |

75 |

kV peak |

No. of pole units |

3 |

3 |

1,2,3 |

1,2,3 |

1,2,3 |

1,2,3 |

nos |

Switching Mechanism |

solenoid |

solenoid |

solenoid |

Mechanical Latch |

solenoid |

Mechanical latch |

___ |

Switching Frequency(V1) |

1200 |

1200 |

1200 |

1200 |

1200 |

1200 |

Ops/Hr |

Switching Frequency(mech) |

___ |

____ |

180 |

60 |

180 |

60 |

Ops/Hr |

Closing Time |

115 |

115 |

115 |

115 |

115 |

115 |

ms |

Opening time |

50 |

50 |

50 |

30 |

50 |

30 |

ms |

No. of Auxiliary contact |

4NO+4NC |

4NO+4NC |

4NO+4NC |

4NO+4NC |

3NO+3NC |

3NO+3NC |

___ |

Auxiliary contact rating(AC) |

___ |

____ |

500/16 |

500/16 |

500/16 |

500/16 |

V/A rms |

Rated control Voltage(AC) |

110/240/415 |

110/220 |

110/220 |

110/220 |

110/220 |

V rms |

|

Rated control Voltage(DC) |

24/46/110/220 |

24/110/220 |

24/110/220 |

24/110/220 |

24/110/220 |

24/110/220 |

V rms |

Closing coil crush current (110/220V) |

25/25 |

25/25 |

9/4.5 |

9/4.5 |

9/4.5 |

9/4.5 |

Amp |

Holding coil crush current (110/220V) |

2.5/1 |

2.5/1 |

2/1 |

____ |

2/1 |

____ |

Amp |

tripping coil crush current (110V) |

------ |

------ |

------- |

1.5 |

_____ |

1.5 |

Amp |

Application/Rated Performance |

|

|

|

|

|

|

|

Motor |

|

|

3500 |

3500 |

6000 |

6000 |

KW |

Transformer |

|

|

4800 |

4800 |

7500 |

7500 |

KVA |

Capacitor |

|

|

!800 |

1800 |

3000 |

3000 |

KVAR |

Weight |

23 |

23 |

23 |

28 |

34 |

49 |

Kg |

Dimension H |

285 |

285 |

316 |

316 |

380 |

380 |

mm |

W |

220 |

220 |

210 |

305 |

245 |

350 |

mm |

D |

260 |

260 |

400 |

400 |

500 |

500 |

mm |

W |

170 |

170 |

327 |

327 |

365 |

365 |

mm |

D |

222 |

222 |

162.5 |

162.5 |

172 |

172 |

mm |

|

11 |

11 |

9 |

9 |

12 |

12 |

mm |

Sub Category

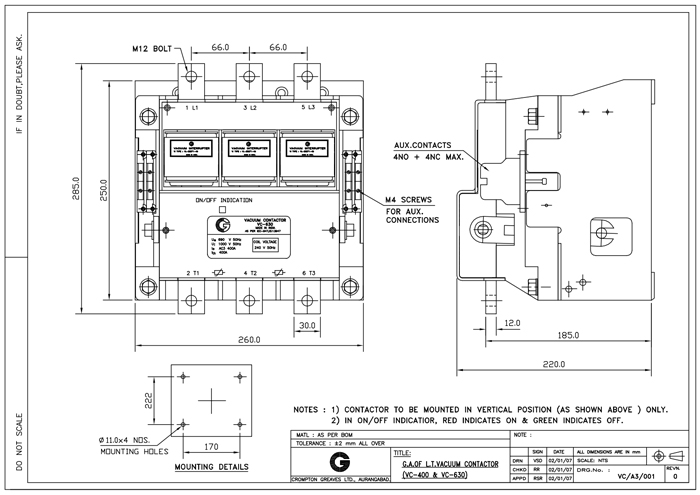

| OA Drg LTVC VC-400 & VC-630 |

| OA Drg LTVC VC-400 & VC-630 |

|